|

|

| Laser Materials Processing Division |

Atomic Layer Deposition

Atomic layer deposition (ALD) is a vapour phase technique capable of producing thin films of variety of materials including oxides. Based on sequential, self-limiting reactions, ALD offers exceptional conformality on high-aspect ratio structures, thickness control at the Angstrom level, and tunable film composition. With these advantages, ALD has emerged as a powerful tool for deposition of metal oxide thin films and nanostructures for many industrial and research applications.

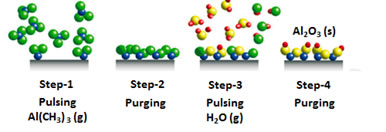

ALD is based on surface controlled thin film deposition. During coating, two or more chemical vapours or gaseous precursors react sequentially on the substrate surface, producing a solid thin film as shown in schematic below for case of growth of Al2O3 using Al(CH3)3 and H2O precursors. Most ALD coating systems utilize an inert carrier gas flow through the system and precursors are injected as very short pulses into this carrier flow. The carrier gas flow takes the precursor pulses sequentially to the reaction chamber, followed by purging. The schematic of ALD chemical processes involved in growth of Al2O3 film and image of thermal ALD system (Model: TSF200, Make: Beneq Oy.) kept in clean room at ONEL. LMPD is shown below

Schematic of ALD coating process

Image of thermal ALD system at LMPD, RRCAT

|

|