|

|

| Laser Materials Processing Division |

CO2 laser development for material processing and Nanoparticle synthesis

Laser Power Supply Development & Instrumentation

Development of 10 kV Pulsed Power Supply for 600 W V-Fold CW CO2 Laser

Commercially available 100 W CW CO2 lasers have limited life of 3-4 years. These lasers becomes non-functional due to deterioration of gas filled in these laser systems. We have developed a technology to refill proper gas mixture in these laser systems.

Highlights:

- Power supply is based on two-switch forward convertor topology and consists of a single phase rectifier with filter, MOSFET-based two-switch forward converter and high frequency transformer.

- Power supply includes short circuit and over current protections for its safe operation.

- Power supply is housed in a 19 inch, 3U size sub-rack unit.

- Pulse power supply has been successfully tested at its rated specifications using a dummy load.

Peak output voltage: 10 kVpk

Pulse width: 5 μsec

Pulse repetition rate: 5 kHz

|

Front panel and inside view of indigenously developed 10 kV pulsed power. |

|

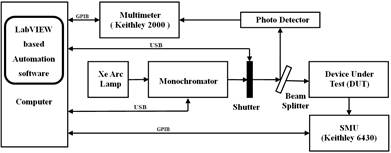

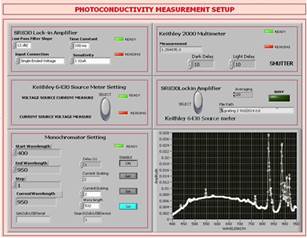

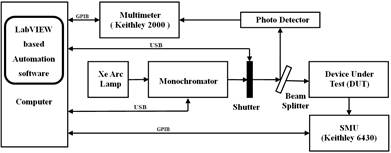

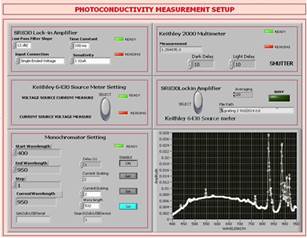

Automation of Photoconductivity Experimental Setup

- Basic aim of the experimental setup is to measure the photocurrent from a device under test (DUT) as a function of wavelength.

- Automation is indispensable for the coordinated operation of various instruments, data collection and plotting.

Highlight of the developed software:

|

Photoconductivity experimental setup with automation |

Controls various functions of the following instruments which are interfaced to a PC:

- Zolix Omni-λ Series Monochromator: extracts desired wavelength spectrum (400 - 700 nm) from a broad band source.

- Keithley Source Measurement Unit (Model 6430): measures photocurrent of DUT.

- 6½-Digit Digital Multimeter, Keithley make (Model 2000): measures photocurrent from reference Silicon photodiode

- Microcontroller based Motorized shutter: used to keep DUT in dark for a defined period before measuring photocurrent for a new wavelength.

|

GUI of photoconductivity set up. |

Publication: A. Verma et al., Proc. 3rd National Conf. Nanoscience & Instrumentation Technology, June 6-7, 2015, NIT, Kurukshetra.

|

Breakdown Maintenance and up keep of laser system controllers

- Break down maintenance of the power supply of EXSPLA make Nd:YAG laser system

- The fault has been identified as a faulty IGBT in simmer power supply card of the laser.

- The fault has been rectified and the laser has been restored to its previous functioning capacity.

|

|

|