|

|

| Laser Materials Processing Division |

Laser-assisted rejuvenation for enhanced fatigue & corrosion resistance of steel parts

Fatigue and corrosion account for a majority of industrial failures. There is a strong need for a practical technique for rejuvenation of in-service components operating under fatigue & corrosion.

Rejuvenation of Inside Surface of Intergranular Corrosion-Damaged Type 304 Stainless Steel Tube through Laser Surface Melting (LSM)

- Intergranular corrosion (IGC) accounts for failure of many austenitic stainless steel (SS) components operating in chemical and process industries.

- Availability of a practical technique for rejuvenation of IGC-damaged components would be greatly useful in extending useful life of in-service engineering components.

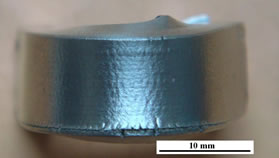

- In this respect, effectiveness of laser surface treatment was demonstrated for rejuvenating inside surface of IGC-damaged 304 SS tube (OD: 90 mm; ID: 84 mm), which is often the requirement in most of the industrial applications.

Highlights:

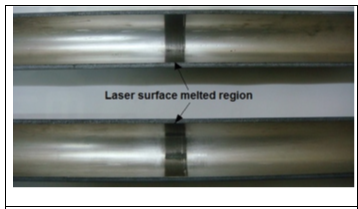

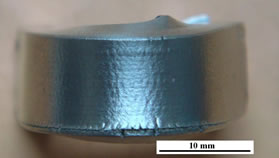

- Laser surface melting treatment of inner surface of intergranular corrosion-damaged type 304 stainless steel (Fig.1) not only erased previous IGC damage, but also restored its degree of sensitization close to that of untreated condition.

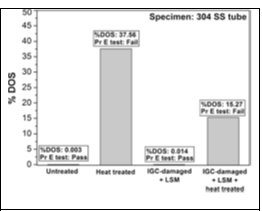

- Laser surface-melted specimens successfully passed ASTM A262 practice E test, thereby not displaying susceptibility to intergranular corrosion.

- Subsequent exposure to susceptible temperature (973 K) brought about enhancement in IGC susceptibility of laser rejuvenated surface of 304 stainless steel tube (Fig.2).

- Laser beam maneuvering arm has been used to carry out laser surface melting for repair of IGC inside the tubular parts.

Potential Applications: For rejuvenation of IGC-damaged in-service austenitic stainless steel components.

|

|

Fig.1: Internal surface of 775-mm-long SS tube showing laser surface-melted region (20 mm wide) at the center of the tube. |

Fig.2: Results of DL-EPR and ASTM A262 Practice E tests on 304 SS specimens in (i) untreated, (ii) heat-treated (700 °C/24 h), (iii) IGC-damaged + LSM and (iv) IGC damaged + LSM + heat-treated (700 °C /24 h) conditions. |

Publication: R.K. Gupta et al., J. Mater. Eng. Perform., 29, 1600-1608 (2020)

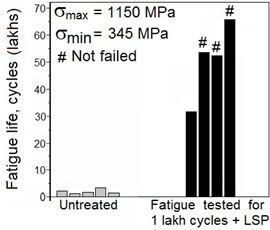

Rejuvenation of fatigue -damaged SAE 9260 spring steel through laser shock peening (LSP)

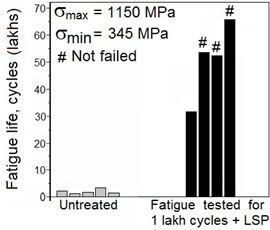

- LSP was highly effective in extending life of partly-fatigue damaged (after enduring ~ 50 % of mean fatigue life) spring steel specimens.

- With respect to mean fatigue life of ~2 x 105 cycles (under experimental test conditions) for untreated specimens, LSP-rejuvenated partly fatigue damaged specimens exhibited more than 15 times higher fatigue life (Fig. 1.).

|

Fig.1: Comparison of fatigue lives of untreated & LSP-rejuvenated fatigue damaged spring steel specimens. |

| Publication: P. Ganesh et al., Materials & Design, 54, 2014, 734-741.

|

|

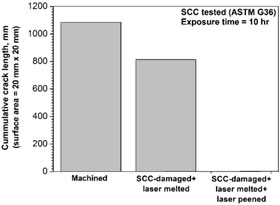

Rejuvenation of stress corrosion cracking (SCC) damaged 304L stainless steel (SS) through a new hybrid laser surface treatment (HLST)

- A new HLST approach, combining laser surface melting (LSM) & laser shock peening (LSP), has been developed for rejuvenating SCC-damaged 304L stainless steel specimens.

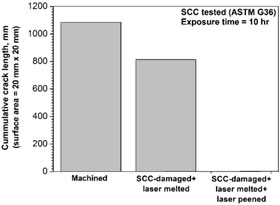

- With respect to as machined specimens, laser-rejuvenated specimens demonstrated significantly reduced susceptibility to SCC in chloride environment (with minor increase in mean surface roughness) than as machined specimen (Fig. 2).

- The results of the study are particularly applicable to shallow SCC damage.

|

Fig.2: Comparison of cumulative crack lengths generated on machined & laser-rejuvenated surfaces of 304L SS specimen after accelerated SCC test. |

| Publication: R. K. Gupta et al., J. Mater. Eng. Perf., 24(6), 2015. 2569-2576.

|

|

Rejuvenation of intergranular corrosion (IGC) damaged 304 SS through laser surface treatment

- Laser surface melting of IGC-damaged 304 SS quite effective in sealing surface damage.

- With respect to CW CO2 laser, pulsed Nd:YAG laser-rejuvenated surface demonstrated significantly suppressed micro-structural damage & IGC-susceptibility.

- Laser-rejuvenated specimen did not exhibit susceptibility to IGC (Fig.3).

Fig.3: Comparison of IGC susceptibility of (A) IGC-damaged and (B) laser- rejuvenated 304 SS determined through ASTM A262 practice E.

Publication: R. K. Gupta et al., Lasers in Manufacturing & Materials Processing, 2(3), 2015, 135-147.

Potential applications: Rejuvenation of in-service automobile leaf spring and SS components operating in chemical and nuclear industry.

|

|

|

Best viewed in 1024x768 resolution

|