|

|

| Laser Materials Processing Division |

|

Materials joining for in-house applications

|

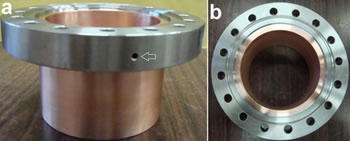

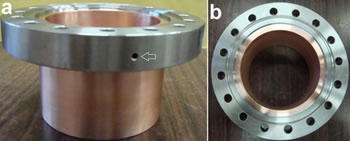

Copper-316L stainless steel brazed transition joints made without electroplating

- Brazed transition joints between OFE copper and 316L stainless steel (SS) are extensively used in particle accelerators all over the world.

- Widely accepted practice for vacuum brazing of such transition joints involves electroplating of SS parts with nickel or copper to enhance its wettability.

Highlights:

- Sound, heremetically sealed (helium leak rate ≤ 2 x 10-10 mbar.lit/s) and bakeable brazed transition joints between OFE copper and unplated 316L SS have been developed (Fig. 1)

- Major contributing factor for establishment of sound transiton joint was ultra-clean environment of the indigenously built vacuum brazing furnace.

- Elimination of electroplating step would translate into significant reduction in total product development time.

|

| Fig.1: (a) Side and (b) top views of vacuum brazed port joint between OFE copper and unplated 316L SS. |

Publications: Abhay Kumar et al., International Journal of Advanced Manufacturing Technology, 87(9), 2016, 2639-2651.

|

| |

|

|